MAINTENANCE WORK

Hammer Replacement:

Hammer replacement

Hammer recharging

Rotor and crusher roller recharging

Replacement of belts, rollers, and tension drums

Crusher:

Replace the table liner segments.

Replace the roller tires.

Complete roller replacement.

Replace the roller protection covers.

Replace the roller arm covers.

Replace the chairs and sealing discs of the rollers.

Replace the table ring (dam ring).

Replace the gas diffuser plates (nozzles assembly).

Replace the gas diffusion cone (air guide cone).

Repair the worn-out liner of the feed chute and reinforce with square bars.

Replace the VRM roller cylinder.

Replace the liner plates (recharged steel, thickness = 20mm, 914x515mm, weight: 73kg) of the VRM body.

Complete replacement of the scraper blades in the reject chamber.

Replace the wear plates of the scrapers.

Replace the base plate of the reject chamber (26m²).

Replace the water injection tubes with their protection (density).

Rotary Valve:

Replace the 6 sealing plates with a maximum clearance of 3mm.

Replace the 6 rubber sealing plates.

Replace the body lining.

Replace the rotor.

Disassemble, repair, and reassemble the valve.

Replace the expansion joint and repair the sheet metal part.

VRM Separator:

Disassemble the upper part.

Replace the valve guide.

Replace the upper seal.

Replace the rotor fastening bars.

Replace the rotor.

Replace the upper and lower bearings.

Replace the wear plates of the rotor.

Replace the vanes.

Anti-wear recharging of the casing.

VRM Bucket Elevator:

Replace the wheel segments.

Replace the deformed buckets.

Replace the two guide bushings of the return sprocket.

Replace the complete chain.

Replace the dragging chain under ESP.

Preheating Tower Cooking Line EVS Tower Area (Preheater):

Open and close the inspection doors of the towers.

Disassemble the splash boxes of the tower and replace the damaged sheets.

Replace the load retention bricks and concrete supports.

Rotate the material descent and connect it to the discharge chutes.

Install/disassemble various insulations in the tower.

Remove and install the C2, C3, C4, C5 doors for inspection.

Disassemble/repair/reassemble the furnace feeding flap.

Install the inspection doors in the tower, size 1000×500.

Install the inspection doors in the tower, size 500×500.

Install air shock system.

Install the cardox tubes.

Repair the conditioning tower.

Install measuring points.

Replace the cylindrical skirt of cyclones C1, C2, C3, C4, and C5.

Replace the complete skirt with its supports.

General maintenance of the flap (unlocking, centering, guiding).

Replace the crusher hammers and recharge the hammers.

Vertical Cement Mill (Leuch) Cement Zone:

Replace the ceramic lining segments of the table.

Replace the ceramic lining segments of the rollers.

Complete roller replacement (VCM).

Replace the table ring (dam ring).

Replace the gas diffuser plates (nozzles assembly).

Replace the gas diffusion cone (air guide cone).

Repair the worn-out liner of the feed chute and reinforce with square bars.

Replace the VCM roller cylinder.

Replace the liner plates (recharged steel, thickness = 20mm, 914x515mm, weight: 73kg) of the VCM body.

Complete replacement of the scraper blades in the reject chamber.

Replace the wear plates of the scrapers.

Replace the base plate of the reject chamber (26m²).

Replace the water injection tubes with their protection (density).

VCM Separator:

Replace the valve guide.

Replace the upper seal.

Replace the rotor fastening bars.

Replace the rotor.

Replace the wear plates of the rotor.

Replace the upper and lower bearings.

Bucket Elevator:

Replace the wheel segments.

Replace the deformed buckets.

Replace the two guide bushings of the return sprocket.

Replace the complete chain.

Replace the dragging chain under ESP.

Cement Line: Ball Mills:

Replace the mill liners.

Replace the partition elements.

Recondition the air slide.

Restore dust collection.

Change the fan turbine and recharge the turbine.

Repair the casing, hoppers, silos, elevator, air slide, chutes, etc.

Replace the elevator wheel segments.

Replace the deformed elevator buckets.

Replace the two guide bushings of the return sprocket.

Replace the complete chain.

Disassemble separator.

Repair the separator turbine and internal parts.

Recondition conveyor belts, replace rollers, change belts.

Sarl Refratech

MENU

About us

Who are we

Our means

Our acheivements

Maintenance work

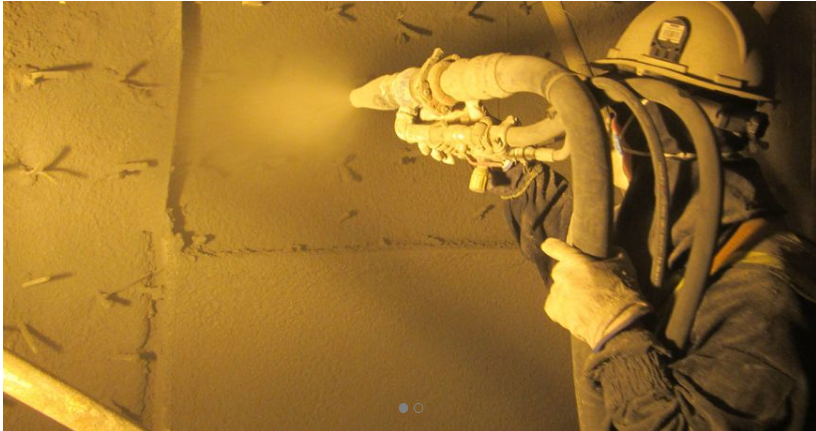

Refractory works

COORDINATES

commerce national :

Tel : +213 6 60536231

+213 770525010

E mail : commercial@refratechalgerie.com

commerce national :

Tel : +213 6 60536231

+213 770525010

E mail : commercial@refratechalgerie.com